Construction Specifications

The ECS/DTR Advantage

ECS/DTR is one of the largest independent specification writing firms in the country, bringing knowledge of 100’s of products to your design and production team.

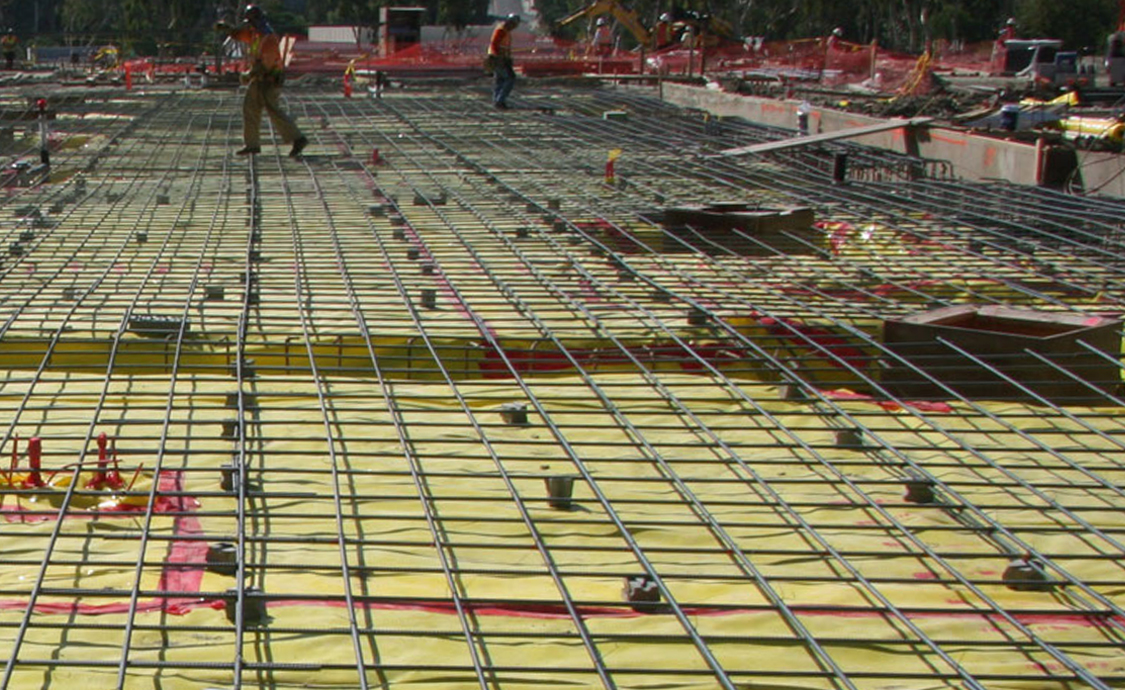

We have extensive experience in developing technical building specifications that comes with hundreds of projects, billions of dollars in construction costs, multiple offices, technical architects and support staff, along with some of the best resources in the country all in one firm.

Nearly twenty years ago we developed the studio approach to providing our clients with the best technical services in the country. We have employed staff from various backgrounds and experiences and created an environment that allows us to learn from our joint experiences, both old and new. In one year, our technical staff is exposed to the technical experience that a traditional architect may be exposed to in a seven to eight-year period. With a good deal of us working on as many as 40 or more projects a year, including high rises, courthouses, city halls, libraries, mixed-use projects, public safety stations, research labs, military facilities, universities, private + public education, hospitality projects and large scale retail and more… we have a lot of knowledge to share.